CeRam-Kote by Freecom, Inc.

CeRam-Kote is a product line developed by Freecom, Inc., a company known for its specialized protective coatings. These coatings are engineered to offer advanced corrosion protection and abrasion resistance, making them ideal for use in a variety of industrial applications. Here are some of the key characteristics and uses of CeRam-Kote coatings:

Key Characteristics

Corrosion Resistance: CeRam-Kote coatings are designed to provide a robust barrier against corrosion, which is essential for extending the lifespan of equipment and structures exposed to harsh environments.

Abrasion Resistance: These coatings are highly resistant to wear and tear, making them suitable for applications involving heavy mechanical stress and movement.

Chemical Resistance: CeRam-Kote coatings can withstand exposure to a range of chemicals, contributing to their durability in diverse industrial settings.

Thermal Stability: Some variants of CeRam-Kote are formulated to maintain their protective qualities at high temperatures, making them suitable for use in environments with extreme thermal conditions.

Applications

Oil and Gas Industry: CeRam-Kote coatings are commonly used to protect pipelines, drilling equipment, and storage tanks from corrosion and abrasion.

Marine Industry: These coatings are applied to ships, offshore platforms, and other marine structures to guard against the corrosive effects of saltwater and marine organisms.

Industrial Equipment: CeRam-Kote is used in the manufacturing sector to protect machinery, conveyors, and other equipment exposed to harsh operating conditions.

Infrastructure: Bridges, towers, and other structural components benefit from CeRam-Kote coatings due to their excellent protection against environmental stressors.

Application Methods

CeRam-Kote coatings are typically applied using techniques such as airless spray, brush, or roller, depending on the specific product and the requirements of the application. Proper surface preparation is crucial to ensure optimal adhesion and performance of the coating.

Advantages

- Extended Equipment Life: By protecting against corrosion and abrasion, CeRam-Kote extends the service life of industrial equipment and structures.

- Reduced Maintenance Costs: The protective qualities of CeRam-Kote decrease the need for frequent maintenance and repairs.

- Versatility: The wide range of available formulations allows CeRam-Kote to be used in various industries and applications.

Overall, CeRam-Kote by Freecom, Inc. offers a versatile and durable solution for protecting assets in challenging environmental conditions. Whether you're dealing with the corrosive effects of saltwater, corrosive chemicals, or the wear and tear of mechanical operations, CeRam-Kote coatings help to safeguard your investments and ensure long-term performance.

- 432-263-8497

- www.ceram-kote.com

- 432-263-5269

Products

Big Spring USA

Big Spring TX 79720

USA

Ships

HB044028

Barge | Flag: Uruguay

Maritime News

Shipbuilding - JV Company Orders Containership Pair

Trump Administration Drops Gauntlet on UN Fuel Rules, Threatens Tariffs

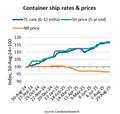

Second-hand Containership Prices Soar in the Face of Soft Shipping Rates

“2 Days, 50 Ports”: New Wave Media Acquires Port of the Future Conference & Exhibition